FLY II

JUST FLY!

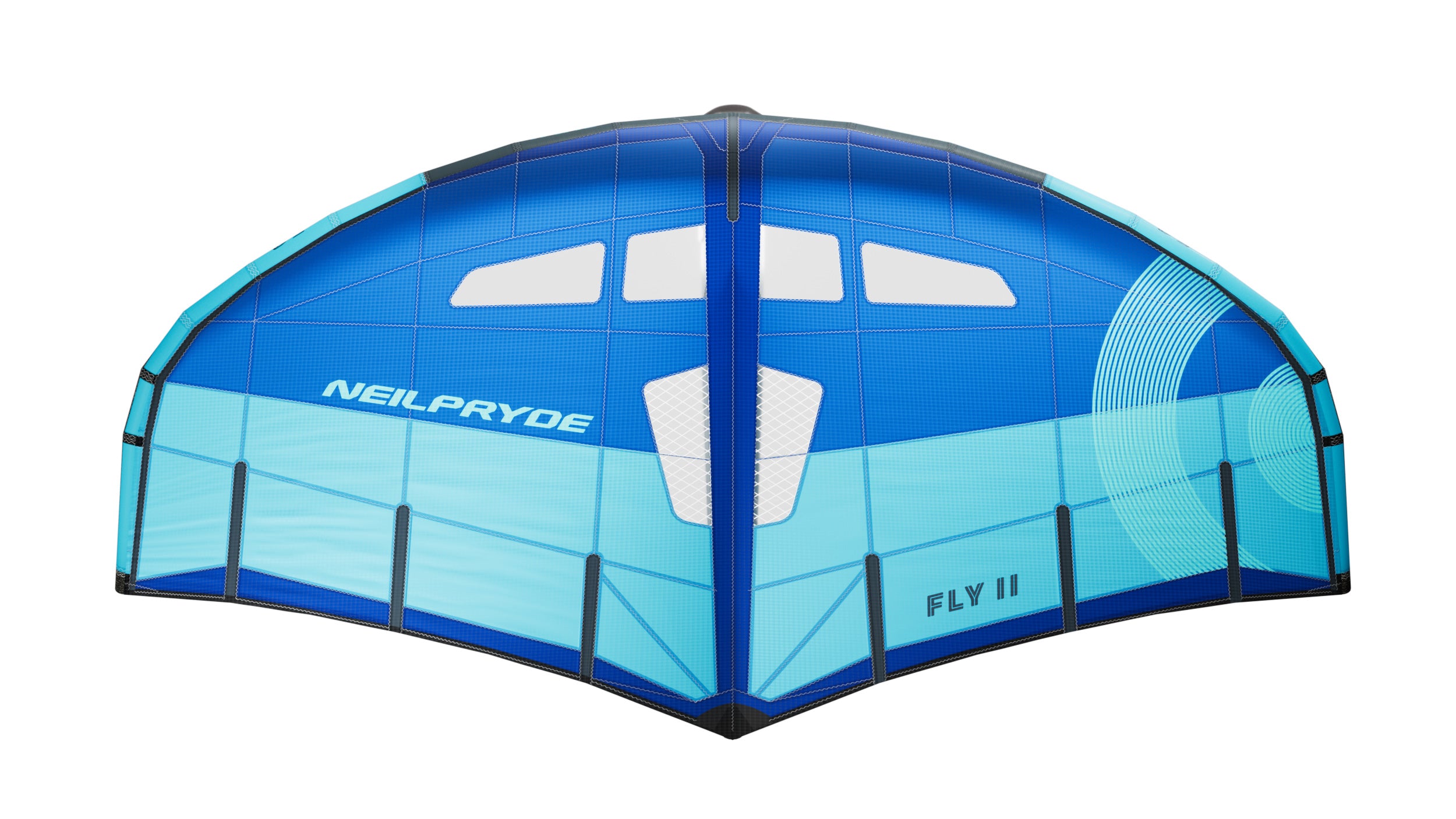

The 2024 FLY II represents an evolutionary leap from the original model that features new materials, even more advanced 3D flying shapes, and a host of enhancements aimed at improving performance and enhancing the user experience.

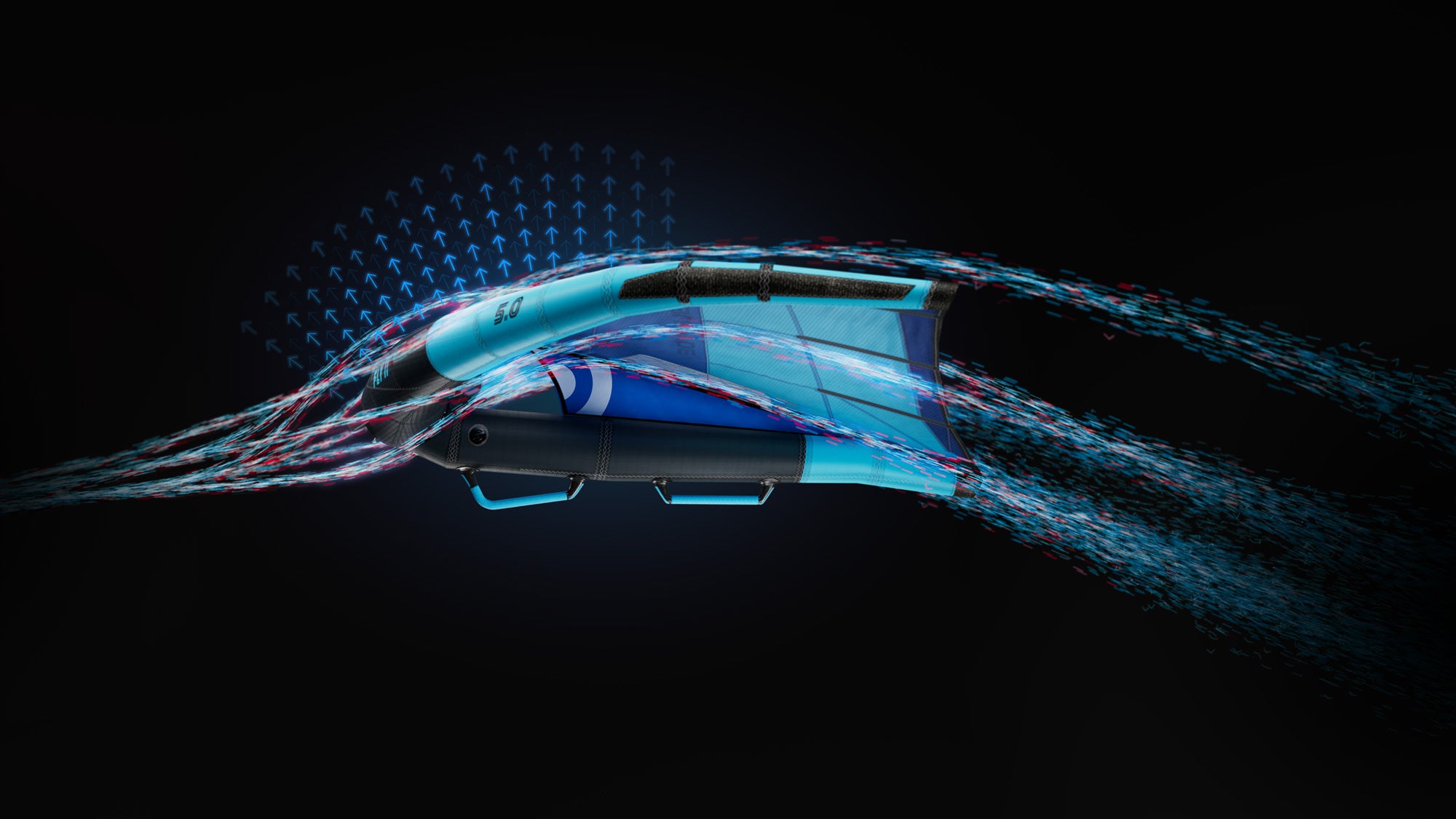

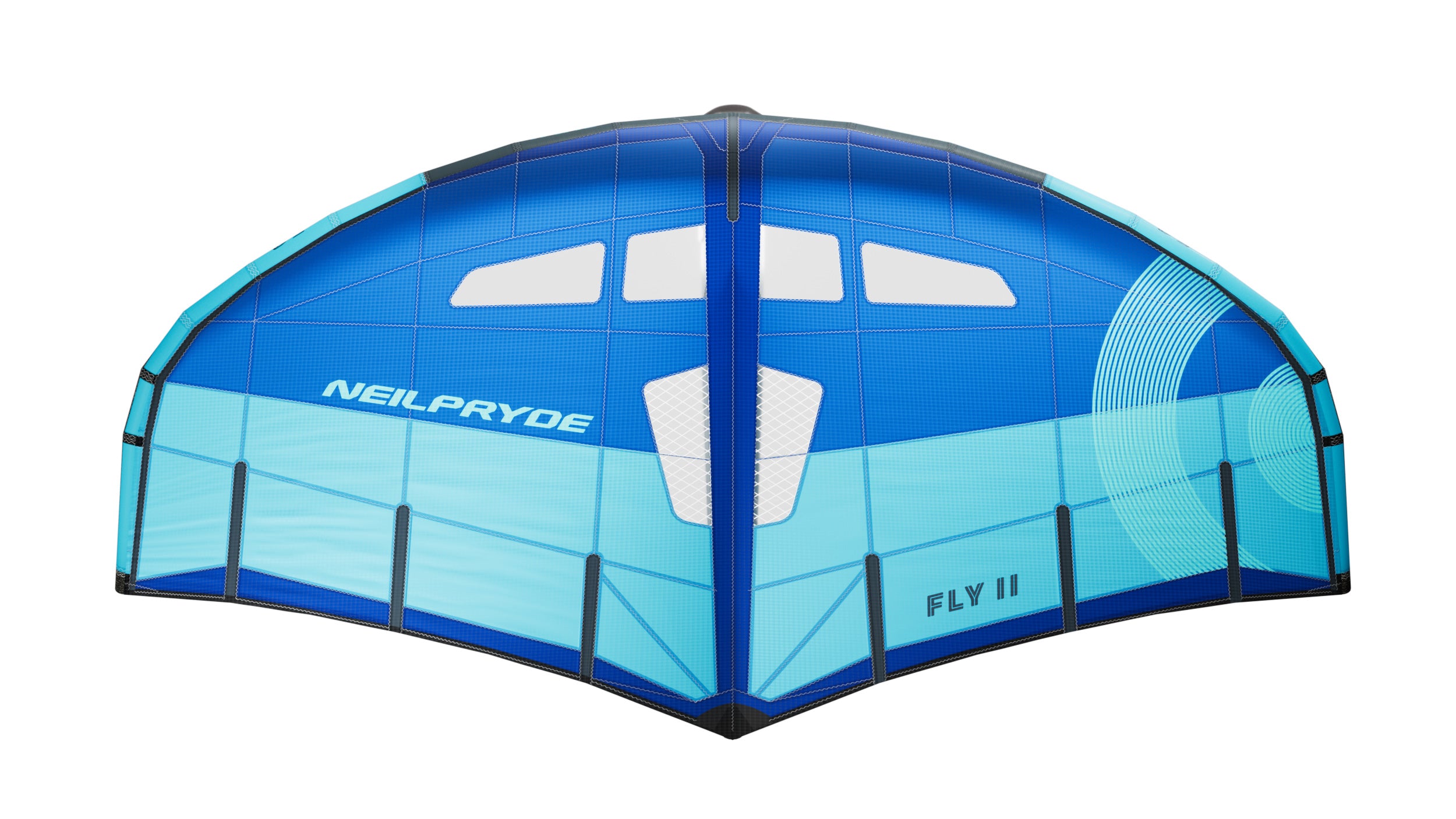

Continuing with the unique high lift coefficient concept, it features an even stiffer airframe and a new twist profile, greatly enhancing handling and control in high wind conditions. The canopy tension distribution, originally derived from windsurfing sail design, has been fine-tuned to improve upwind speed and handling through upwind maneuvers. The dihedral front profile has been reshaped for increased stability when sheeted in, particularly beneficial for harness-equipped riders. Additional Leading Edge (LE) segments at the wingtips not only reduce drag but also provide added stiffness, enabling the wing to point higher. The vented strut has been updated with an additional stiffener at the Leading Edge (LE) in the center, enhancing stability in the area ahead of the fill panel, making the wing much more forgiving during tacks.

The FLY II is now constructed entirely from Teijin LE dacron, greatly enhancing its shape durability. The trailing edge panels forward of the frame are made from Challenge Code 95 for exceptional stiffness and long lasting shape control. The back windows now feature a dyneema X-ply for the optimum balance between visibility, light weight and structural integrity, while the front windows are clear PVC. The windows have been redesigned and repositioned to improve visibility.

The wide range of size options between 4.0 and 6.0 are unique to the Fly II. We have simplified the sizing between 1.8 to 3.5 compared to the previous model to make the selection process much easier.

Key Features

FLY II

UNIQUE HANDLE DESIGN

Calibrated positions for effortless balanced flight, ergonomic design to reduce fatigue and position the wing at the optimum flight angle.

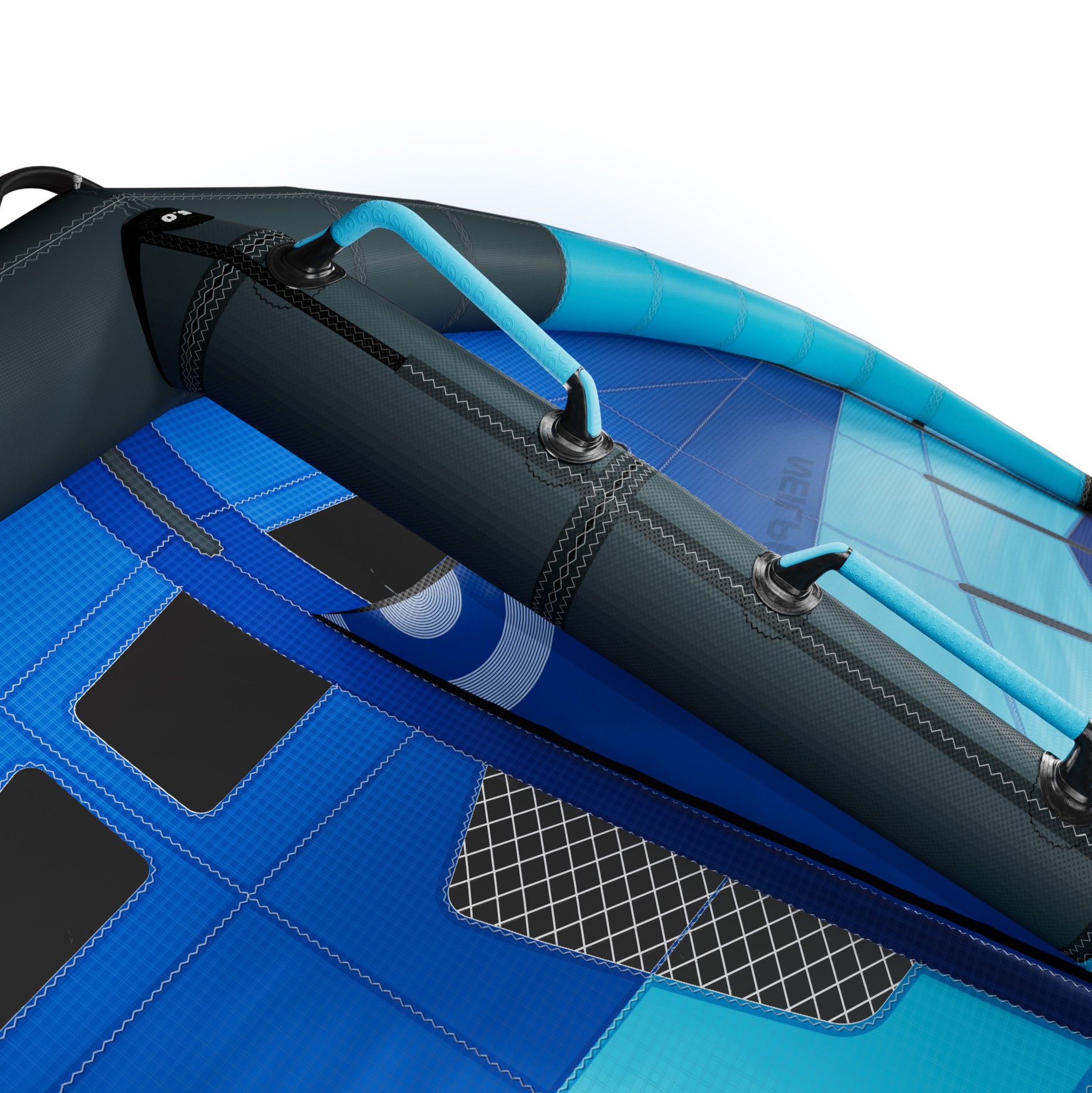

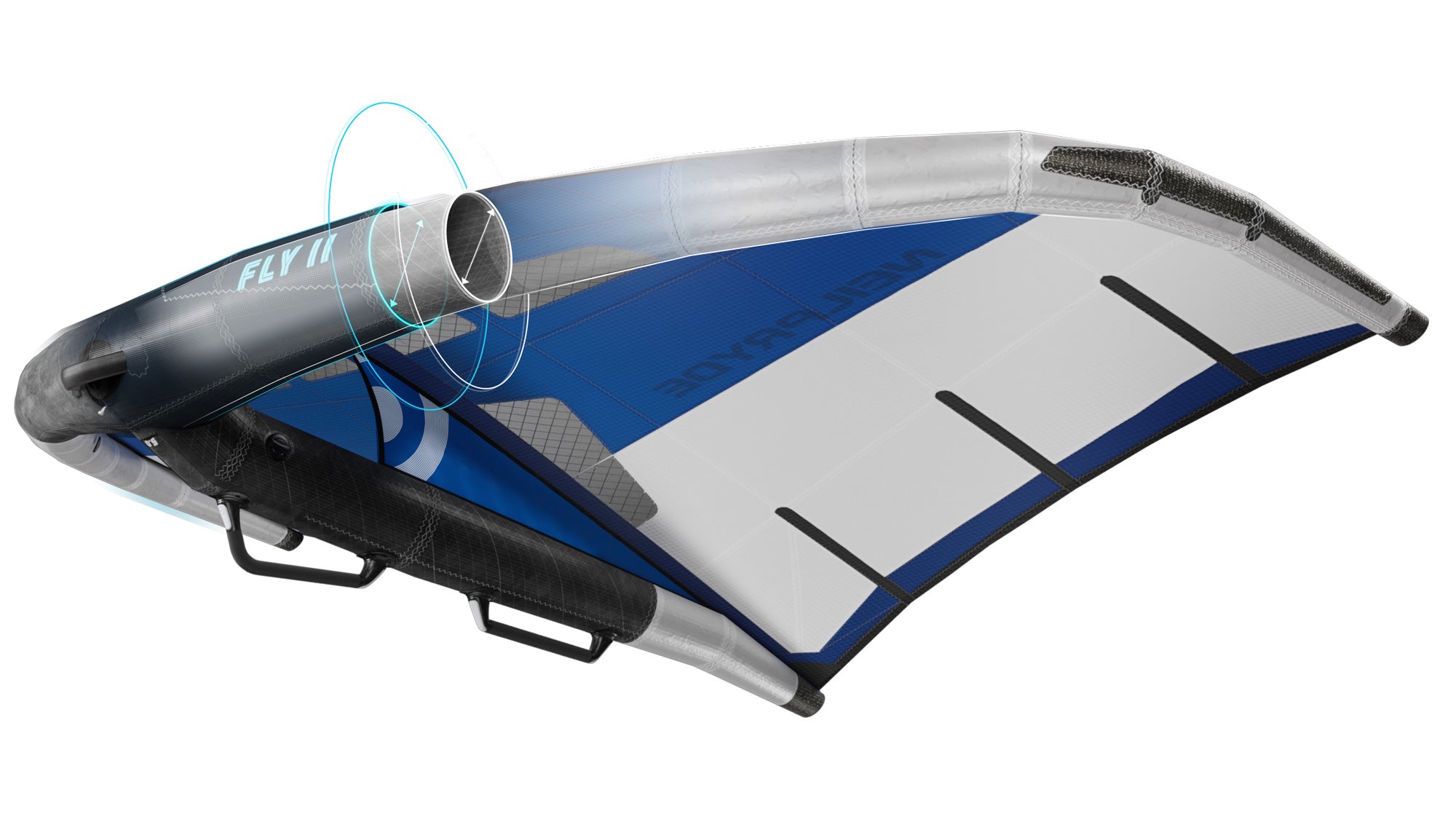

HIGH QUALITY BLADDER WITH ANTI-TWIST SYSTEM

Fixing the bladder in different spots in the tube prevents it from twisting and therefore protects it from breaking when inflating. It also makes changing the bladder super easy and long lasting shape control.

Bladder made in Germany.

CANOPY MATERIAL

The trailing edge panels forward of the frame are made from Challenge Code 95 for exceptional stiffness and long lasting shape control.

Transverse paneling holds shape under load and reduces stretch over time.

VENTED STRUT

Allows the pressure to equalize the two sides of the wing.

SEPARATED AIR CHAMBER

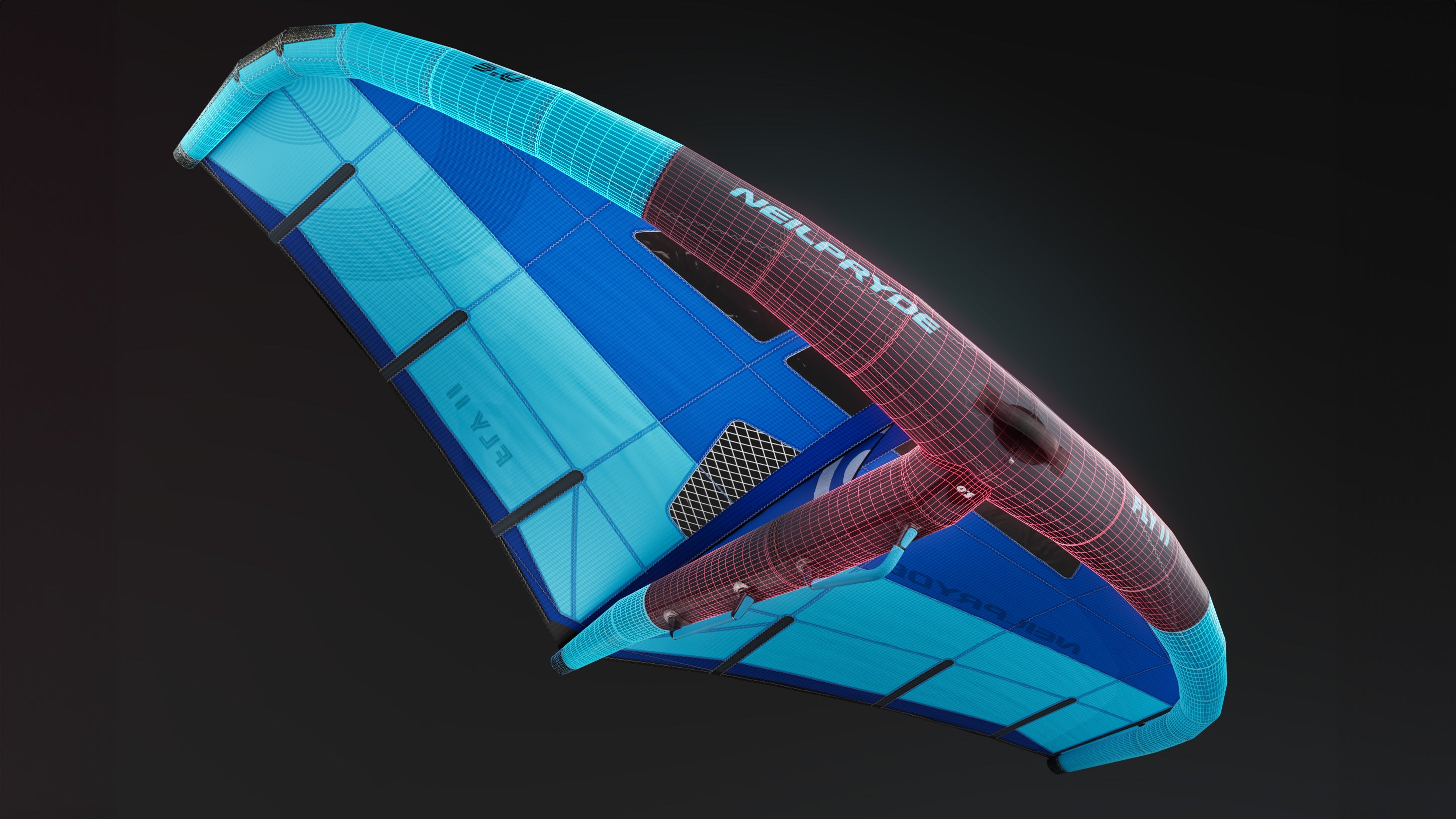

The partition adds safety, increases the Leading Edge stiffness and allows the wing to be deflated more quickly.

DEVELOPMENTS

Since the 1st generation of FLY

The Leading Edge (LE) diameter has been decreased 9-12% for the FLY II PRO (moreso in larger sizes) to reduce drag and allow higher inflation pressures.

The Leading Edge has been reduced by 3-6% for the FLY II (moreso in larger sizes) to reduce drag and allow higher inflation pressures.

Evolved window shape adds outboard elements to improve visibility when sheeted in. X Ply Windows in front and back.

Evolved window shape adds outboard elements to improve visibility when sheeted in. PVC Windows in front. X Ply windows at the back.

Wingtip sweep has been increased to improve upwind stability and and for more control while holding the wing in a neutral position. The pointing ability is improved due to moved Center of Effort slightly to the leech.

Wingtip sweep has been increased to improve upwind stability and and for more control while holding the wing in a neutral position. The pointing ability is improved due to moved Center of Effort slightly to the leech.

The new wings have much more precise shaping built in, while retaining the transverse paneling that holds it‘s shape under load and stretches much less over time.

The new wings have much more precise shaping built in, while retaining the transverse paneling that holds it‘s shape under load and stretches much less over time:

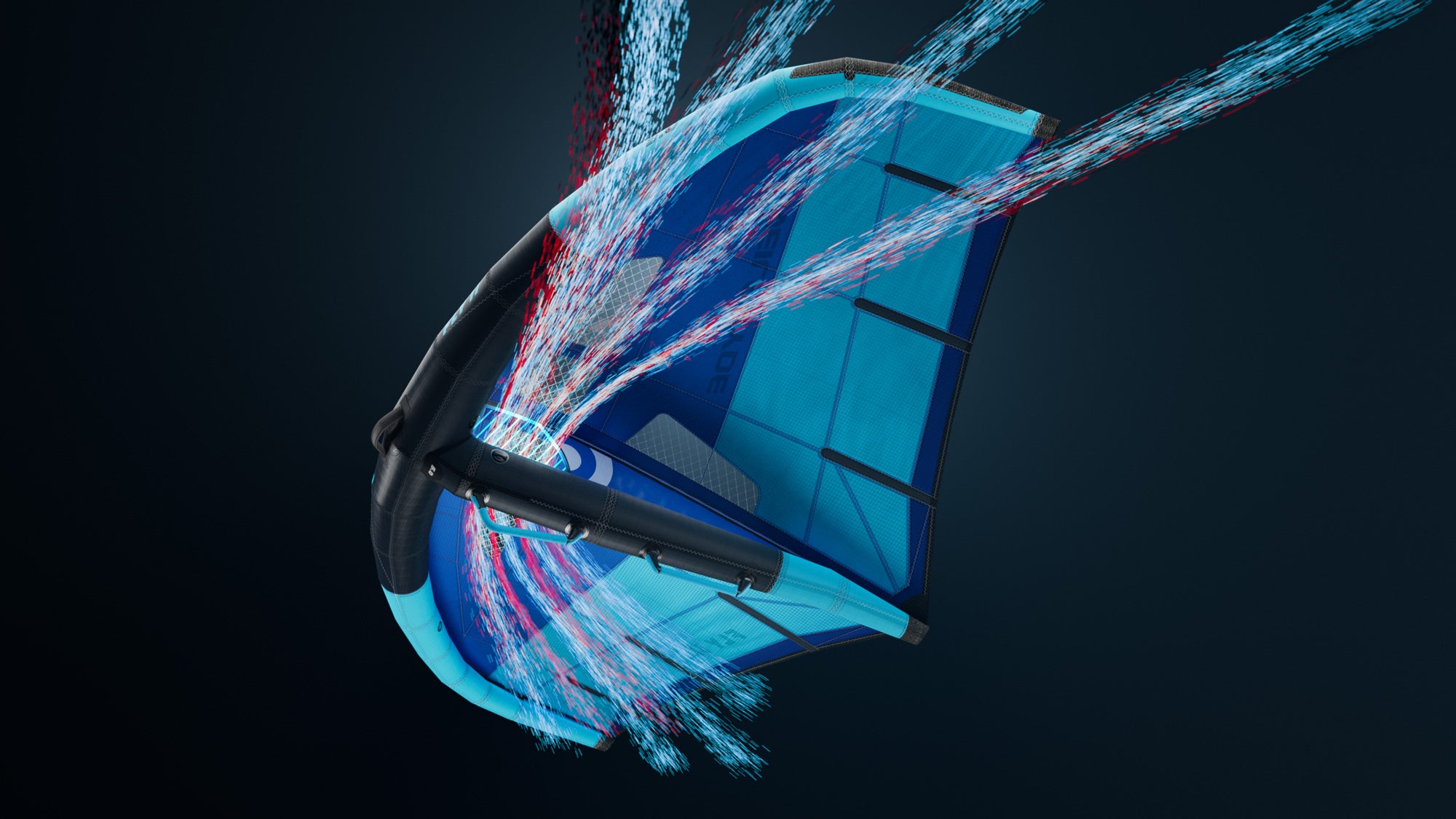

HIGH LIFT CONCEPT

Due to the highly refined LE geometry and entry shaping, each wing produces the maximum thrust (power and acceleration) for its size. This dramatically increases the range, allowing riders to use a smaller wing than is typical in each set of conditions. The result is easier handling and greater maneuverability.

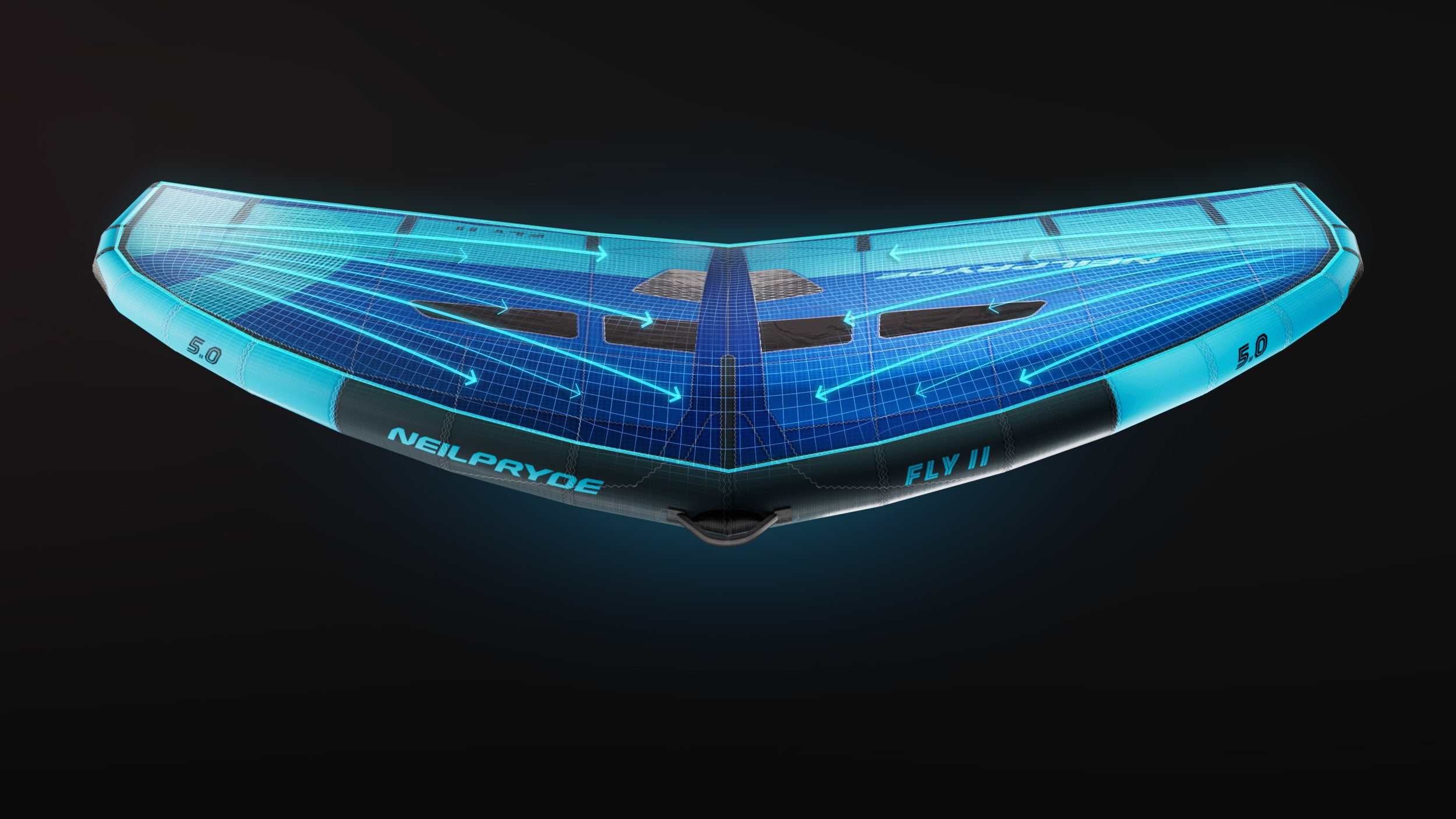

HIGH TENSION CANOPY WITH STRUCTURED CAMBER LENS

The 3D shape of the canopy leading edge is defined by a series of transverse panels that converge at the wingtips. This leverages the LE Tube structure to maximize tension in the critical entry sections – the result is more lift and a higher stall angle for better acceleration in light winds, and the ability to fly efficiently at low angles of attack for better control and higher top speeds in strong winds.

VENTED STRUT

The large opening between the LE and the front of the fill panel (which connects the canopy to the strut) allows the pressure to equalize across the two sides of the wing. This improves overall performance and makes the wing even more stable.

EVOLUTION

A year after introducing the FLY, we have achieved additional development milestones and are proud to unveil the enhanced and refined models: FLY II PRO and FLY II. The development of the FLY concept has been based on using the most proven materials, examining the technical development of wingfoiling down to the smallest detail and adjusting all the set screws.

SHAPE DIFFERENCES

The Fly II and Fly II PRO are very close. The major shape differences are the LE diameter (PRO is much smaller) and that - because it has a flatter entry angle to leverage the leading edge (LE) stiffness of the Aluula and reduce drag - the Fly PRO canopy appears slightly smaller when shown as flat pieces.

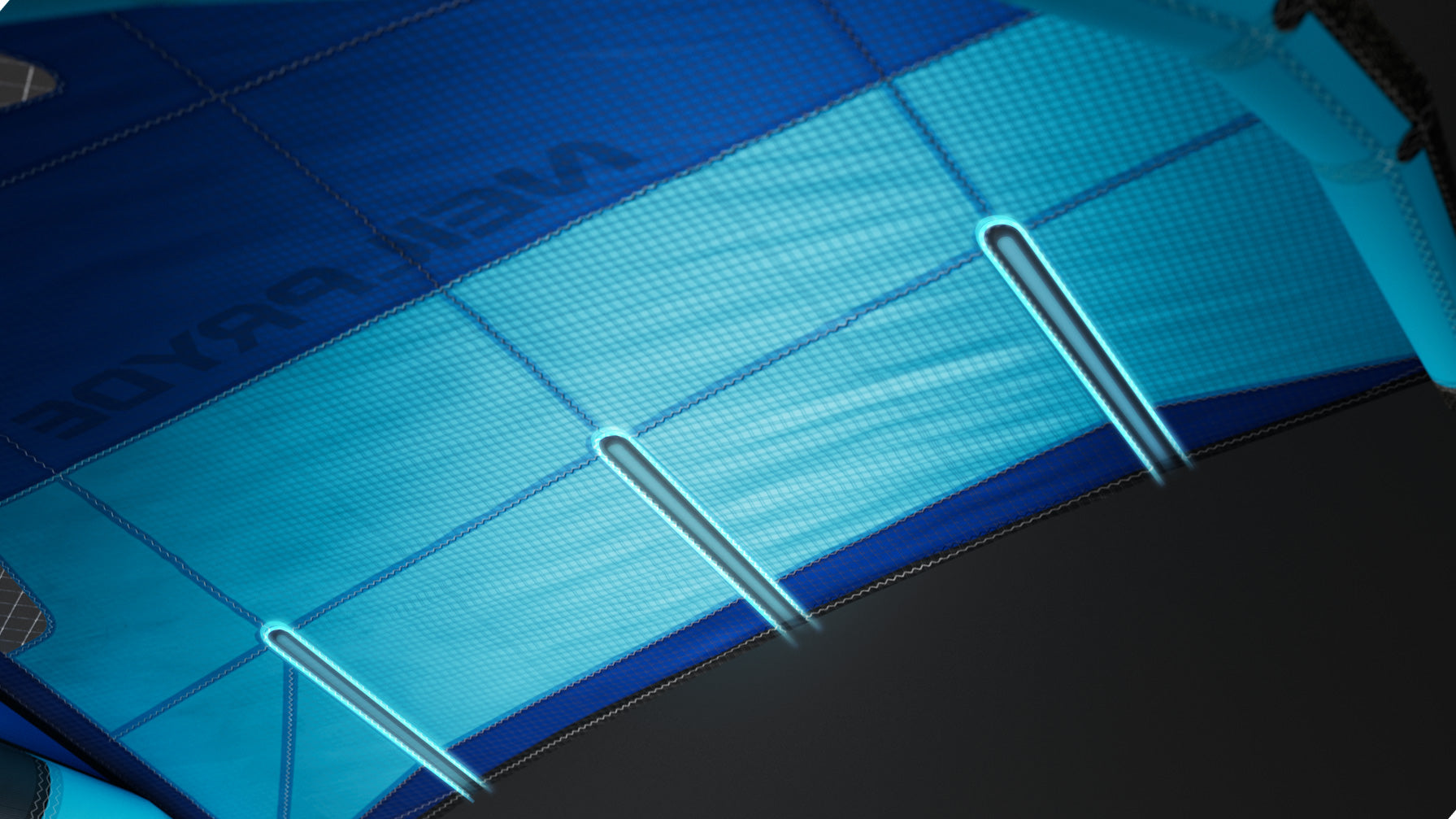

Transverse Canopy Paneling

The new wings have much more precise shaping built in, while retaining the transverse paneling that holds it‘s shape under load and stretches much less over time. There are now 4 stitched transverse panels on each side of the wing compared to only 2 in the previous model, vastly increasing shape stability.

Integral Batten System

Sewn-in composite battens create a flat, fast trailing edge with minimum flutter.

Staggered material weights on LE

The use of an ultra-light, high-tenacity woven polyester at the wingtips and back of strut results in a very light ‘feel’ due to reduced swing weight.

UNIQUE HANDLE DESIGN

Calibrated positions for effortless balanced flight, ergonomic design to reduce fatigue and position the wing at the optimum flight angle.

BLUE OR ORANGE

Style your wing.

BLUE

BERRY

WING SIZE RECOMMENDATION

As our high lift coefficient allows you to use a significantly smaller wing in any given conditions, please use this guide to appropriately size your wing to your usual riding conditions.

*Min recommended wind for 100kg+ rider weight = 10 - 12kts

40-60kg

60-85kg

85-100kg +

3.5m

3.5m

3.5-4.0m

3.5m

3.5-4.0m

4.0-4.5m

3.5-4.0m

3.5-4.5m

4.5-5.0m

4.0-4.5m

4.0-5.0m

5.0-5.5m

4.5-5.0m

4.5-5.5m

5.5-6.0m

5.0-5.5m

5.0-6.0m

6.5m*